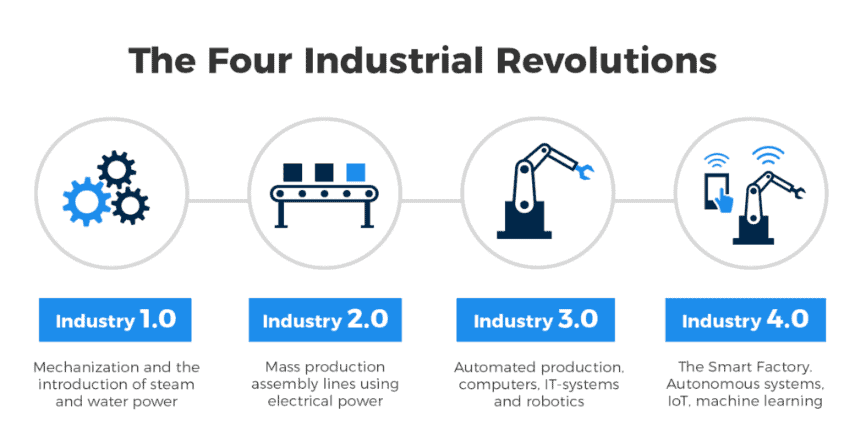

We are in the midst of a significant transformation in the operating world, thanks to the digitization of production floors. This transition is so revolutionary and significant that it received the name Industry 4.0 to represent the fourth revolution that took place in the manufacturing sector.

Industry 4.0 Upgrading Technological Capabilities

A crucial part of the fourth revolution in the industry is the ability of computers to communicate with each other to make decisions without human involvement. A combination of cyber systems, the internet, and other advanced tools enable the smart factory to become a reality. As a result of the support of smart machines and systems, which are evolving day by day, our factories will become more efficient and more productive. Ultimately, the real power of Industry 4.0 is the sharing of information between machines and systems.

Industry 4.0 Applications

While many organizations are delayed in adopting the approach, others are already embracing change, preparing themselves for a future where smart machines will improve their business. Here are just a few of the possible applications.

Identifying Opportunities: Sharing information and gathering a lot of data, in addition to today’s smart analytics capabilities, enable systems to provide information on maintenance, performance, and other issues, as well as analyze the data to identify patterns and insights in a short time frame accurately.

Upgrading Logistics and Supply Chains: An online and connected supply chain can be available (Agile) and adaptable when new information arrives. For example, if the change of weather delays shipping, the system can proactively adjust and change production and distribution priorities.

Autonomous Equipment and Vehicles: Apart from the vision for road cars, autonomous equipment is already widely used. For example, some ports that operate cranes and autonomous trucks to unload shipping containers efficiently and are immune to human error.

Robots: Today, the concept of ‘robot’ is not just a vast enterprise. From picking products in warehouses to preparing them for delivery, autonomous robots can support production quickly and safely.

3D Printing: This technology has improved significantly over the last decade and has progressed primarily to the prototype stage for actual production.

While Industry 4.0 is still evolving and looking futuristic, its benefits are already significantly evident in the field. Organizations that will be able to advance and adopt the advanced capabilities and tools will benefit in the long run.